What Is ED-155?

At Appareo we get A LOT of questions about ED-155. These questions are sometimes in reference to our recoverable data modules and other times in reference to our airborne image recorders.

What Is ED-155?

At a really high level, ED-155 is the minimum operational performance specification for a lightweight flight data recording system. The specification was created in response to industry pressure to provide lighter flight recorders as smaller aircraft were increasingly receiving pressure to carry flight recorders, but the predominant international flight recorder standard at the time (ED-112) was constructed primarily to address requirements for air carriers to have onboard cockpit flight and data recorders. The accident dynamics (where the crash occurs, how much energy is in the crash, what the potential for fire size/duration may be) are much different on large jetliners when compared to helicopters or smaller fixed-wing business aircraft. Especially with consideration for rotorcraft, weight and size are at a premium and lighter solutions that more appropriately address the survivability requirements of a recorder in a smaller aircraft accident were necessary to be created.

The specification was also created to encourage the modernization of flight data recording technologies, moving away from standards that support old recording media like magnetic tape.

How Is ED-155 Organized

The specification is constructed to cater to a variety of different data recording needs. It includes:

- Generals standards applicable to all recorder types

- Standards for Deployable Recorders

- A description of requirements that cater to different kinds of recorders, including:

- Cockpit Audio Recording Systems (CARS)

- Think of this as a cockpit voice recorder, although the specification also includes ambient audio data acquisition

- Aircraft Data Recording Systems (ADRS)

- Think of this as a flight data recorder

- Airborne Image Recording Systems (AIRS)

- Think of this as a cockpit camera

- Data-Link Recording Systems (DLRS)

- Think of this as a cockpit voice recorder but for digital data that is transmitted and received rather than cockpit voice

- Multi-Function Recording Systems

- Think of this as a system that combines two or more of the functions above

- Cockpit Audio Recording Systems (CARS)

The specification as a result provides a very comprehensive set of requirements that address almost any conceivable type of recording system.

Why This Can Be Confusing

This is confusing because there are no specific international mandates that decompose some of the five different categories of ED-155 and call on a specific subset of requirements to be compliant with a standard. Rather, the standard provides guidelines for a variety of different systems.

Tell Me About The General Standards

The general standards that address all recorder types include requirements for basic operation, safety, retention of recorded information, and survivability. The survivability standard covers requirements for impact/shock, crush, and flame survivability that are in excess of tests encountered in standards like RTCA DO-160. There is also a requirement that the survivable memory component of the flight recorder be bright orange and labeled with the words FLIGHT RECORDER in black letters.

What a Deployable Recorder Is And How It Relates

A deployable recorder is a recorder that is designed to come free from an aircraft in an accident sequence. In general, the objective of these recorders is often to pair them with a locating beacon and a means of flotation to allow the recorder to float and be recovered independently of the wreckage for incidents that occur over deep water. These recorders are typically mounted on the exterior of the aircraft. In Appareo’s experience, the smaller nature of the aircraft that are often under consideration for ED-155 recorders has made it unusual for us to encounter interest in deployable recorders of this size. Regardless, the standard provides for additional environmental and survivability testing criteria for ED-155 compliant recorders designed with this feature in mind.

What Is Considered A Cockpit Audio Recording System (CARS)

A CARS is a system that records both ambient area audio data (i.e. the noise inside the cockpit) as well as the pilot audio channel(s). The ambient area audio data allows accident investigators to listen to particulars of an incident, which can sometimes provide insights regarding aircraft mechanical failures (e.g. forensic analysis of turbine engine noise). The recording of pilot communications provides insights into pilot decision-making, communication between pilots, and interactions with air traffic control. In some recorder systems, the pilot audio channels and the cockpit area microphone data can be delivered by different system components.

The specification declares the performance and recording requirements (e.g. total recording capacity, recording delay tolerances, etc) for both the ambient and pilot sources while adding requirements or provisions for other capabilities (e.g. requiring a build erase function to be present). The standard also provides for the test requirements and procedures necessary to demonstrate a CARS’ performance against the standard’s requirements.

What is an Aircraft Data Recording System (ADRS)

An ADRS is a system that records digital flight data in an uncompressed format. The ED-155 standard allows for a variety of aircraft data sources, which is an effort to accommodate the wide variety of aircraft on which such recorders were intended to be installed. For example, acquiring flight data on helicopters that are not equipped with digital data buses as a portion of the avionic equipage may not be impractical – as a result, the standard allows for sensors interior to the ADRS to record such data (e.g. pitch/roll data from an IMU, GPS data, etc). Alternatively, a smaller aircraft used for business transport purposes may provide practical access to a digital data bus (e.g. ARINC 429) and the standard provides performance requirements for recording from such sources.

Much like the CARS, the ADRS specification declares performance and recording requirements for the ADRS while also specifying which parameters must be recorded, and at what frequency, for a unit to qualify as an ADRS.

What is an Aircraft Image Recording System (AIRS)

Aircraft image recording systems are equipment that is deployed for the intent of capturing image data regarding aircraft operation, which is typically then synchronized in time with the recording of other recorder types. For example, synchronizing AIRS with a CARS will provide synchronized playback of image and audio data from a flight. Likewise, synchronizing AIRS and ADRS can provide data to create synchronized cockpit videos with flight animations.

The AIRS systems are separated into six different classes. The classes are described by alpha characters (A through F) and are organized as follows:

- This Class provides a general image of the cockpit including instruments and a view of the external environment (through the glareshield)

- This Class provides a recording of the data-link message display

- This Class provides for a means of recording flight data where it is not possible or prohibitively expensive to otherwise do so

- This Class provides a means for capturing heads up displays

- This Class provides a means of capturing other camera images present to pilots (e.g. as a means of capturing cargo or cabin views presented to pilots)

- This Class provides means for capturing an external view of the aircraft

The standard provides guidance for operational considerations, like what portions of the cockpit to capture in the image frame and provisions for data security/privacy (e.g. preventing AIRS data from being easily played back by non-investigative personnel, as well as performance requirements in the areas of recording capacity, recording delay, and image compression.

What is a Data Link Recording Systems (DLRS)

Often when people refer to flight data recorders the physical interface between the flight data recorder and the aircraft is often done through ARINC 717. The objective of a DLRS is to record the messages passing to and from the aircraft via a digital means, which is typically accomplished using a standard avionic digital interface like ARINC429. In this manner, the DLRS is attempting to acquire information like data exchanged through CPDLC, digital ATIS, NOTAM delivery, etc.

Although Appareo’s recording solutions (both AIRS and RDM) can support acquiring DLRS data we typically don’t list such recorders in our compliance tables because the FANS, CPDLC, and related on-aircraft features that necessitate and enable such recorders don’t typically appear in aircraft under consideration for ED-155 style, lighter, flight data recorders.

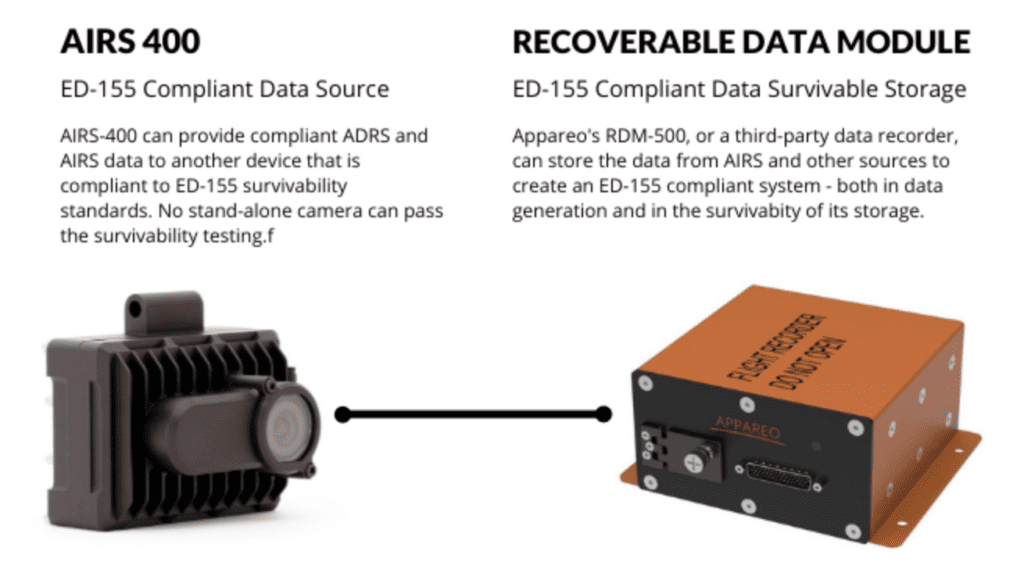

How does AIRS-400 Comply with ED-155?

AIRS can do all of the data acquisition and recording to show compliance to a variety of ED-155 requirements by itself, however, to show full compliance to the standard the camera needs to be hooked up to another module. This section of the document will further discuss why a second module MAY be required for some installations. For the overwhelming majority of AIRS installations a second module is not required because the AIRS cameras are:

- Capable of surviving most aircraft accidents without one; and,

- In most of the world, there is no regulatory requirement to specifically be equipped with such a recorder

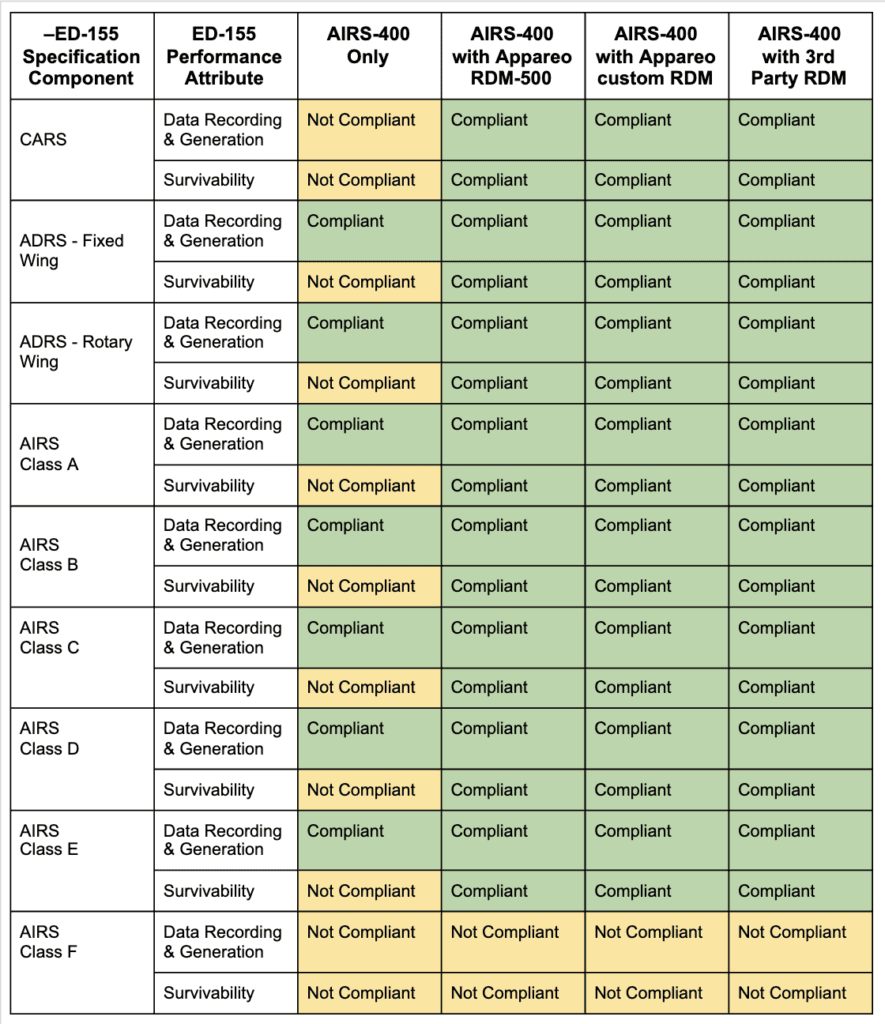

The sections below discuss the ways in which the AIRS-400 is not compliant with the ED-155 standard and discuss why those noncompliances exist. Then, finally, a table will provide the combinations of AIRS-400 and other products that can be used to show full compliance to the ED-155 standard.

ED-155 | Non-Compliant Appearance

AIRS-400, in an off-the-shelf configuration, is not compliant with ED-155 section 2-1.14.4. This portion of the standard requires that the recorder be bright orange in color with black letters that say, “FLIGHT RECORDER.” In general, Appareo finds our customers to prefer a less obvious, intrusive, color for a product mounted within the cockpit in plain sight. It would be possible to create a variant of our AIRS that would be bright and orange and marked in this manner, but in general, Appareo finds that our customers do not want the camera marked in such a manner because they believe it looks bad in the cockpit.

ED-155 | Non-compliant Survivability

In general, the AIRS-400 is significantly more survivable than our previous cockpit camera product, the Vision 1000. The product is not, however, compliant with ED-155 section 2-4.2.4.

It is not compliant with this portion of the standard because compliance with the flame survivability requirement requires the presence of a phase change material, a material that is used to absorb the heat energy in the event of a fire. The mass of phase change material that is necessary to absorb the amount of heat energy products are subjected to in this test is roughly 4 times the volume, and 4 times the weight, of Appareo’s AIRS-400 product. This creates a large, unattractive, product package for mounting into the ceiling of a cockpit or flight deck. For a customer that requires ED-155 or ED-112 flame survivability, a recoverable memory module mounted in a more convenient location for a large, heavy product is the right architecture for the deployment of a flight data recording system. This provides the optimal flight data acquisition capability, with a visually attractive and high-performing camera solution providing digital data to a large, less attractive, recoverable module buried out of sight in the aircraft.

ED-155 | Achieving Full Compliance Using Appareo’s New Recorder

Achieving full compliance with ED-155 is possible with AIRS-400 in a number of ways. The first, and perhaps easiest, is to connect the camera to a recoverable memory module of either Appareo or third-party manufacture. For example:

- AIRS-400 could be used to generate data on an analog aircraft, using its internal sensors, and send that data to a large orange flight recorder (which may have no internal sensors, and on an aircraft with limited or no digital instrumentation) to provide the ED-155 ADRS function needed to comply with ED-155, refer to TSO-C197

- AIRS-400 could be used to acquire image data and send that data to a large orange flight recorder to satisfy both the AIRS and ADRS requirement on a modern, digital, aircraft that are not factory equipped with a cockpit/flight deck image recorder

- AIRS-400 could be used to provide ADRS data and the ambient area microphone function to a large orange flight recorder that provides CVFDR functionality on an aircraft with primarily analog instrumentation, greatly simplifying that recording system’s deployment

- Et cetera

There are many different ways in which this new camera, with its high survivability and alignment with ED-155 data acquisition/generation requirements, can help our global customers show compliance to regulations and standards that may invoke full or partial compliance to the ED-155 standard. The table below helps summarize some of the ways in which this compliance can be achieved.

If, after reviewing this write-up and the above table, you’re still trying to understand the standard, your requirements, and how to show compliance, please contact Appareo.

Part of our role in helping our customers to be successful is providing transparent, direct, assistance in navigating these standards to achieve an affordable and conveniently implemented system that truly fits the aircraft while showing compliance to required regulations.

David Batcheller

President & CBO https://appareo.com/2021/08/09/what-is-ed-155/