Tag Archives for " Aviation "

Smart Rudder Bias: Safety-Enhancing Technology for Select Twin-Engine Piston Aircraft

Our GFCTM 600 digital autopilot has been upgraded to feature new safety-enhancing capabilities, including Smart Rudder Bias for select piston twin-engine aircraft. Part of our AutonomiTM family of automated flight technologies, Smart Rudder Bias provides additional assistance against hazardous effects of a one-engine inoperative (OEI) event when appropriately equipped. It also provides pilots assistance in maintaining control of the aircraft while determining the next course of action, simultaneously reducing workload in a high-stress and time-critical flight environment.

“We are proud to be able to offer a new safety tool for twin-engine piston aircraft with the introduction of Smart Rudder Bias, making the GFC 600 digital autopilot the most advanced solution for this class of aircraft on the market today” said Carl Wolf, Garmin vice president of aviation sales and marketing. “With the introduction of Smart Rudder Bias technology, working together with the other Garmin systems onboard, pilots can react to an engine failure by quickly and accurately detecting the issue while simultaneously receiving automatic assistance applying the correct flight control input – providing an additional safety tool not seen before in twin-engine piston aircraft.”

Help manage aerodynamic performance with Smart Rudder Bias

Twin-engine aircraft inherently have aircraft controllability concerns in the event of an engine failure and pilots can expect a significant yaw toward the inoperative engine, resulting in an unstable aircraft state. In addition, due to a sideslip condition and a windmilling propeller, there can be decreased lift on the wing associated with the inoperative engine and simultaneously an increase in drag, all factors contributing to degraded performance and a critical loss in airspeed. Through close integration with multiple onboard Garmin systems, Smart Rudder Bias helps address these major concerns and immediately assists with controllability issues. This gives the pilot time to take the correct action required in order to better maintain positive aircraft control and help keep the aircraft in a safe flight condition.

Positively identify inoperative engine quicker

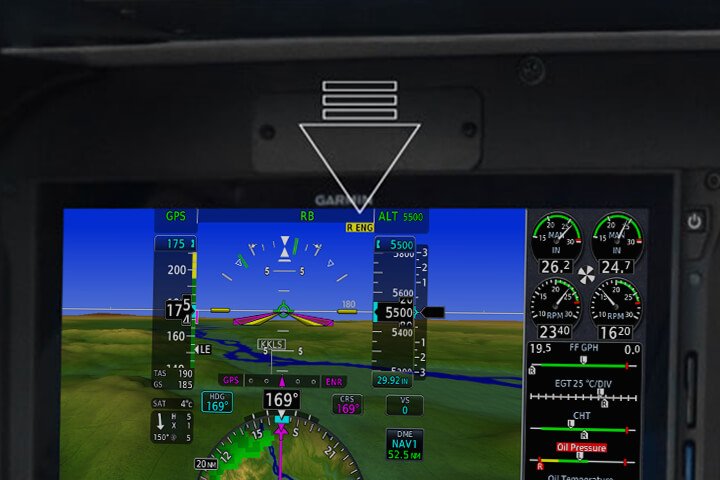

When the aircraft reaches the manufacturer’s published minimum control speed (VMC) during the takeoff roll, Smart Rudder Bias is automatically armed. Smart Rudder Bias continuously monitors engine parameters using Engine Indication System (EIS) data displayed on a G500 TXi or G600 TXi flight display and activates when the system detects a predetermined power differential between each engine. Once activated, rudder force is dynamically adjusted to aid a pilot in providing enough force to the rudder to help control a sideslip. A yellow annunciator for the associated inoperative engine is conveniently displayed along with autopilot annunciations on the G500 TXi or G600 TXi flight display, helping the pilot identify the issue quicker. Smart Rudder Bias can be deactivated via a panel-mounted switch.

Smart Rudder Bias enhances ESP settings for OEI condition

Garmin’s Electronic Stability and Protection (ESPTM) functions independently of the autopilot, working in the background to help pilots avoid inadvertent flight attitudes or bank angles and provides airspeed protection while the pilot is hand-flying the aircraft. Smart Rudder Bias applies enhanced ESP settings tailored to engine-out flight. Roll protection is modified to help correct for the roll tendency caused by the inoperative engine, while underspeed protection activates at a higher airspeed to help keep the aircraft away from the critical VMC speed and the associated loss of positive aircraft control.

PA-31 certified with GFC 600 – optional yaw trim also available

The GFC 600 is also now certified on select Piper PA-31 aircraft, and an automatic yaw trim option is available. Similar to pitch trim, yaw trim allows for manual rudder trim control with the press of a button, and automatic control of the rudder trim when the GFC 600 autopilot or yaw damper is engaged.

Smart Rudder Bias requires a G500 TXi or G600 TXi configured as a primary flight display (PFD) with EIS, which can be shown as a strip on the G500 TXi or G600 TXi, or on a separate TXi display. Additionally, a GFC 600 digital autopilot with the yaw axis option must be installed. Initial certified aircraft with Smart Rudder Bias capability include the Beechcraft Baron 58 and 58A, as well as the Piper PA-31-300, PA-31-310, PA-31-325, and PA-31-325CR. Additional certifications of Smart Rudder Bias will be forthcoming.

For additional information about Smart Rudder Bias and the Garmin Autonomi family of automated flight technologies, visit www.Garmin.com/SmartRudderBias.

The post Smart Rudder Bias: Safety-Enhancing Technology for Select Twin-Engine Piston Aircraft appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/smart-rudder-bias-safety-enhancing-technology-for-select-twin-engine-piston-aircraft/

Configuring Wake Modes to Maximize Battery Life in Cellular Asset Trackers

Operators want to use their expensive machines (loaders, sprayers, excavators, aircraft, etc.) as much as possible, because at the end of the day, business assets are more of an asset when they’re put to work. When a fleet is distributed over a large area, knowing where equipment is so it can be put to work can be a challenge.

Over the last decade, it has become common for larger or more expensive equipment to be delivered from the original equipment manufacturer (OEM) with a telematics standard. Sometimes it’s a simple position reporting modem, other times there’s a huge volume of operating detail being delivered to the cloud. In any event, it makes it much easier for operators to start tracking a fleet of assets when the equipment comes standard with tracking capability.

The challenge

There are still holes when trying to conduct an efficient operation with a full picture of the fleet. These holes exist because many fleets have equipment that did not come with factory telematics.

For example:

- Tenders, dump trucks, and other Milk Run equipment that create the maximum productivity of a working asset also typically do not have stock telematics

- Specialized equipment produced in lower volumes by smaller OEMs, and therefore not factory-equipped with tracking features

- Towed equipment that is not electrified (e.g. trailers, carts, screens, mowers, balers, tedders, rakes, grinders, chippers, etc.) and as a result have no built-in tracking connectivity

- Expensive attachments that are unpowered

- Older equipment that is in good working order but was delivered before connectivity was standard among major OEMs

Considering these holes, you may only be able to track a portion of the fleet. Even if it’s 75%, it’s not good enough. A project can’t happen if only 75% of the equipment is at the site. That makes these holes important to fill, but it also has to be easy. Operators don’t have the time or the interest to assemble a pile of dissimilar aftermarket technology offerings into a fleet tracking solution — they have a business to run.

The good news

In a previous blog (Understanding 4G LTE Categories) we discussed new kinds of cellular technology that have emerged as a portion of 4G offerings. These technologies, specifically NB-IoT and M1, create opportunities for very rugged and affordable “slap and track” cellular asset trackers. These kinds of trackers can be attached to any piece of equipment, and by using their own battery they can report its location for years.

![]()

This can be an easy fix to the problem, but getting real satisfaction out of these solutions is all about managing the battery life of the unit. Why?

- Many rugged asset trackers are made without replaceable batteries in order to achieve an IP67 or IP69K rating. Although these trackers are cheap, they need to be discarded when the battery is used up.

- Trackers with replaceable batteries lose the “easy fix” appeal once you’re spending time tracking down machines to charge their units or replace batteries. The appeal of this solution is ruined if you can’t leave a machine alone for at least a season — ideally for the life of the machine.

So, how do you use “slap and track” solutions to the maximum benefit of your business? I know people hate this answer, but it depends. As you consider your equipment tracking goals, it’s important to understand battery life and wake modes.

Understanding battery life in cellular asset trackers

Battery life is fixed, meaning you start with a bucket of energy and that is all you get. Therefore, to achieve maximum customer value, the focus needs to be about extending the duration of time that a rugged asset tracker can be used.

To maximize that energy:

- Devices need to be off as much as possible

- When on, devices should sparingly use the components that use a lot of energy (e.g. cellular and GPS)

Device manufacturers have put a bunch of battery management tools into these devices, and the asset tracking ecosystem, to make tracking as easy as possible. It varies by manufacturer, but when a device is advertised to have a 5-year lifetime, that’s typically based on an expectation of a few thousand positional reports over its lifetime. That works out to 1-2 position reports per day for five years. So, while the device’s lifetime is marketed in the form of years, in reality the lifetime is based on the number of positional reports utilized.

Understanding how different wake mode configurations affect battery life

Making the most of the battery management tools should get careful consideration as you deploy trackers. We recommend consulting with your tracking services or hardware supplier to dial this in as early as possible. Devices can typically be configured to report in the following ways (organized from most power hungry to least power hungry):

Periodic continuous reporting

For trackers that are integrated into the machine and connected to vehicle power, this is an easy and inexpensive thing to do. However, most customers with battery powered trackers will not want to use this mode. Having the device report every minute, or even every hour, will consume a lot of battery life.

Wake and report on movement

Many asset tracking devices include an accelerometer. These are great because they use minimal energy and can be used to wake the device when it moves. This is helpful if you want to know when equipment is moving from site to site or when equipment has begun working, for example. Depending on the tracker’s capabilities, it might be possible to set the device to report on movement but then to “snooze” for a period of time (e.g. 4 hours). A word of caution, however: if you can’t snooze its reporting behavior, this feature could run through the battery life quickly.

Wake and report on rest

This is related to the movement feature, but it notices when the device stops moving for a period of time (typically configurable) and then reports the device position. It’s an inverted version of the previous feature with the same benefits and challenges.

Start of day / end of day position reporting

This feature is generally easy to configure, easy to implement, and very friendly for battery life. Simply pick a time of day and have the unit report its position at that time every day. This can give you an overview as to where the equipment was left at the end of the day, giving you an opportunity to dispatch resources effectively at the start of the following workday. When combined cleverly with some of the above features (e.g. report equipment position at 5:00 PM, then report on movement in the event someone moves it after hours), it can be used to give an effective and timely overview of fleet positions while using minimal battery.

Wake on demand

This easy to use feature is very powerful and enabled by the newest generation of cellular technologies. For those of you who want to push your glasses a bit higher on your nose and nerd out with us about how this feature works, we’ll dig deeper in a future blog. For this post, we’ll talk about the capability at a high level so you can understand how to exploit it.

Using a computer or mobile device, you ask the equipment to report its location. This feature sends a message over the cellular network, which is stored in a mailbox of sorts. The device periodically checks that mailbox, using very limited energy, to see if it needs to report in. If there’s a request waiting, it reports its location.

The beauty of this feature is that whenever you need to know the location of an asset, you can have the device report in at the push of a button. The report doesn’t come back in seconds, because typically the device is configured to “check the mailbox” at scheduled intervals in order to minimize energy use. However, even waiting a few minutes to get the devices’ location is MUCH faster than driving from site to site looking for it.

Do you want future connectivity advice, insights, and information delivered to your door? Join our email list, and follow us on LinkedIn.

![]() David Batcheller – President & CBO

David Batcheller – President & CBO

https://www.appareo.com/2020/12/14/configuring-wake-modes-to-maximize-battery-life-in-cellular-asset-trackers/

Popular Science Tabs Garmin Autoland One of 2020’s Greatest Innovations

Popular Science, one of America’s oldest and most trusted magazine brands with a legacy of reporting on groundbreaking innovations, recognized Garmin Autoland with a 2020 Best of What’s New Award in the Aerospace category. Autoland is part of our Autonomi family of autonomous safety-enhancing technologies for aircraft, and the world’s first system of its kind for general aviation aircraft. It has the ability to land an aircraft in an emergency should the pilot suddenly become incapacitated or unable to fly1.

After reviewing thousands of products in search of the year’s top 100 innovations, Popular Science unveiled the best breakthrough products and technologies that represent significant advancements and ‘solve an unsolvable problem’ in an announcement last week.

“We are truly humbled and proud to be selected by Popular Science with this honor for our revolutionary Autoland autonomous flight technology,” said Phil Straub, Garmin executive vice president and managing director, aviation. “This recognition highlights our commitment to innovate in the aviation industry. It’s a testament to the entire Garmin team, whose dedication to continuously drive our pioneering vision led to the development of the world’s first Autoland system for general aviation aircraft and changed the way we look at aviation safety.”

For 33 years, the editors at Popular Science have reviewed thousands of products in search of the top 100 tech innovations each year – breakthrough products and technologies that represent significant advancements in their categories. The publication’s Best of What’s New Awards are presented to 100 new products and technologies in 10 categories: Aerospace, Automotive, Engineering, Entertainment, Gadgets, Health, Home, Personal Care, Security, and Sports & Outdoors. Garmin Autoland was chosen among nine other innovations in the Aerospace category, which includes anything that flies or pertains to flight.

“The Best of What’s New Awards showcase the year’s greatest feats of human ingenuity,” said Popular Science Editor-in-Chief Corinne Iozzio. “Even in a year like 2020, innovation has helped us glimpse a future that’s safer, smarter, and more enjoyable than we might have thought possible.”

Garmin Autoland is available as part of the G3000® integrated flight deck on select general aviation aircraft. In the event of an emergency, such as pilot incapacitation, Autoland is capable of completely taking control of the aircraft, avoiding weather and terrain, and landing at the nearest, most suitable airport. Elements taken into consideration when identifying the most suitable airport include a wide range of performance, operational and environmental factors. Throughout an Autoland activation, the system provides simple visual and verbal communications in plain-language so passengers in the aircraft know what to expect. Further, the system will automatically communicate with air traffic control, advising controllers and pilots operating near the aircraft of its location and its intentions.

On approach to land, the system initiates a controlled descent to the airport. Once in landing configuration, the aircraft begins its descent to the runway. On the runway, automatic braking is applied while tracking the runway centerline to bring the aircraft to a full stop. Engine shutdown is also automated so occupants can safely exit the aircraft.

The first certified Autoland system for general aviation aircraft, Garmin Autoland has received FAA certification in the Piper M600, the Daher TBM 940, and the Cirrus Vision Jet as part of the G3000 integrated flight deck. EASA approval was also recently granted to the TBM 940. By the end of 2020, more than 100 fielded aircraft are expected to feature Autoland.

For additional information about Autoland and the Garmin Autonomi family of automated flight technologies, visit www.garmin.com/Autonomi.

family of automated flight technologies, visit www.garmin.com/Autonomi.

The post Popular Science Tabs Garmin Autoland One of 2020’s Greatest Innovations appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/popular-science-tabs-garmin-autoland-one-of-2020s-greatest-innovations/

New Safety-Enhancing Features for GTN Xi Series Navigators

Our GTN Xi Series of navigators now feature even more advanced capabilities, including a Glide Range Ring that helps safety-minded pilots visualize the estimated area an aircraft could reach in the case engine power is lost1. Other new features include the ability to remotely control the radios of another GTN Xi when dual GTN Xi units are installed in an aircraft, quicker page navigation with the addition of customizable dual concentric knob functions, and more.

Xi Series of navigators now feature even more advanced capabilities, including a Glide Range Ring that helps safety-minded pilots visualize the estimated area an aircraft could reach in the case engine power is lost1. Other new features include the ability to remotely control the radios of another GTN Xi when dual GTN Xi units are installed in an aircraft, quicker page navigation with the addition of customizable dual concentric knob functions, and more.

Glide Range Ring

The new Glide Range Ring helps pilots enhance their situational awareness by depicting the estimated area that the aircraft can reach when it’s configured for best glide range in the case of an engine failure. It considers terrain data, as well as wind data when provided by a GDL 69 or FIS-B Source, or calculated winds from a compatible Garmin fight display2, in order to help pilots continuously plan while flying. Further, G500 TXi or G600 TXi flight displays can also show the Glide Range Ring when paired with the GTN Xi while using the GTN Xi GPS guidance as the horizontal situational indicator (HSI) source.

or G600 TXi flight displays can also show the Glide Range Ring when paired with the GTN Xi while using the GTN Xi GPS guidance as the horizontal situational indicator (HSI) source.

Best Glide Airport Indicator

Depicted as cyan chevrons pointing to the recommended airport for the aircraft to glide to from its current position, the Best Glide Airport Indicator1 is selected based upon distance from present location, runway length at the airport, wind data, and airport weather through FIS-B or Sirius XM if available on the aircraft. If desired, the Best Glide Airport Indicator can be displayed by itself or with the Glide Range Ring also shown.

Nearest Airport list updated to show Glide Check

The Nearest Airport list now indicates which airports are estimated to be reachable on glide by displaying a green check mark indication next to the airport identifier1. If the pilot’s criteria for nearest airports would have excluded an airport that is estimated to be within glide range, the system will automatically add these airports back to the Nearest Airport list and display the Glide Check, while also highlighting the runway length and surface type with a white box if these figures do not meet the previous nearest airport criteria set by the pilot.

Remote radio control and new radios page

When dual GTN Xi navigators are installed, pilots can now remotely control and tune the radio frequencies on both units from a single GTN Xi navigator. Pilots can control both the Comm and Nav radio tuning, in addition to volume level, which is an especially useful function for quick radio tuning in a busy flight environment. Additionally, pilots can cycle through radios of both GTN Xi navigators by pressing the dual concentric knob on just one GTN Xi. A new radios page displays all Comm and Nav frequencies (active and standby) of both units, as well as volume levels. The radios page can be quickly accessed from the frequency keypad page or as a preset user field button. From this page, pilots can easily flip the respective active and standby frequencies. Also new, pilots can load a frequency to the active or standby position of either GTN Xi from applicable airport or waypoint information pages.

Quicker page navigation with dual concentric knob

Similar to other Garmin navigators, the dual concentric knob can now enable quicker access to select pages. The outer knob now allows the pilot to intuitively cycle between pages on their GTN Xi, while the inner knob can now support functionality related to the current page being displayed, such as scrolling through lists or zooming in on maps. A new locator bar works in conjunction with the outer knob and indicates the current page while also displaying which page is next. Pilots can allocate and customize up to nine pages to be controlled by the outer knob including Map, Nav, Flight Plan, Traffic, Weather, Fuel Planning, and many more.

Other GTN Xi series improvements

Additional features of the latest GTN Xi update include:

- New user fields such as the ability to display Flight ID, a radios page shortcut, the current time (including seconds), distance and bearing from a selected waypoint, and current position formatted in latitude and longitude;

- Database sync with Garmin GPS 175, GNC 355, and GNX 375;

- Ability to select a default page to display on startup;

- Shortcut to view charts after tapping on airport, departure, arrival or approach from the Flight Plan page;

- And an option to inhibit terrain alert pop-ups and mute traffic alert pop-ups.

These updates for the GTN Xi series of navigators will be available later this month through the Garmin dealer network. A dealer installation charge may apply. The GTN Xi Series also comes with a two-year warranty, which is supported by our award-winning aviation support team. For additional information, visit https://www.garmin.com/GTNXi or contact a local Garmin authorized dealer.

1. Requires additional configuration steps during software upgrade. See Garmin dealer for details.

2. Compatible flight displays include G500/G600 TXi, G500/600, G3X Touch, GI 275, and G5 (with GAD 13/GTP 59).

The post New Safety-Enhancing Features for GTN Xi Series Navigators appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/new-safety-enhancing-features-for-gtn-xi-series-navigators/

Top two security issues for connected machines

It is important for our machines to be connected. From industrial asset trackers for inexpensive off-road vehicles to satellite telemetry solutions for business jets, original equipment manufacturers (OEMs) are counting on embedded connectivity solutions to deliver high business value for them and their operators. To deliver this value, these connectivity devices are networked to critical onboard engine, hydraulic, display, and navigation equipment to provide the rich data needed to exploit the business value of the connected tractor, loader, or aircraft.

With all of these interconnections and access to critical machine or aircraft systems, there is an obvious need to ensure that such connections are secure. Security is a confusing and acronym-laden space that can leave buyers uncomfortable or uncertain. To combat this, we’ll focus in on the top two areas that you should have a strategy for:

1. The hardware and software on the device itself

2. Transportation of data from device to cloud

Understanding Keys

First, it’s important to understand the concept of a “key” when discussing security concepts for telematic devices. In a simple sense, information is scrambled using an algorithm, and the key unlocks that information. If you’ve ever used paper cutouts over a page of text or a pinwheel decoder to extract a secret message, you’ve experienced a sort of encryption, or cipher, and a key. There are many different manifestations of encryption and key structure, but the concept of an algorithmic encryption and key to enter/exit that encryption are consistent across these concepts.

In a simple sense you can divide security concerns within a telematic device into hardware and software. You need to be confident that the software on the device is genuine, has not been corrupted by some bad actor, and is not attempting to do anything nefarious. You also need to be sure that the hardware is secure, so the electronics are protecting the data resident on the device (including the secret decoder keys that unlock the encryption the device uses to communicate).

Hardware Security Onboard a Device

There are some spectacular tools available to device manufactures to secure applications and storage onboard telematic controllers. For example, Arm TrustZone allows the device manufacturer to secure certain ranges of memory and flash from snooping and sniffing. This security extends to the ability to secure these ranges from the application software onboard the device itself, so even the application running on the device cannot read that data off the flash and send said data to the cloud.

Why is this important? One example of a security vulnerability is to send a false application update to a device, whose express purpose is not to successfully corrupt/replace the application software, but instead is the first component of a multi-stage attack in which the initial attack’s objective is to steal the encryption keys from the device. In such a situation, the application is falsely deployed to the device and retrieves the keys. Even though it fails to update, the device uses the telematic capability of the device to offboard the keys and enable a subsequent, more dangerous attack. With such hardware security enabled, you would not be able to read the protected memory locations, the false application update would be rejected, and the device would continue on its way.

One example of a security vulnerability is to send a false application update to a device, whose express purpose is not to successfully corrupt/replace the application software, but instead is the first component of a multi-stage attack in which the initial attack’s objective is to steal the encryption keys from the device. In such a situation, the application is falsely deployed to the device and retrieves the keys. Even though it fails to update, the device uses the telematic capability of the device to offboard the keys and enable a subsequent, more dangerous attack. With such hardware security enabled, you would not be able to read the protected memory locations, the false application update would be rejected, and the device would continue on its way.

A different approach to hardware security is through the utilization of trusted platform modules (TPM). In this case the keys are stored entirely within a different, secure, integrated circuit that is separate from the core product’s processor/memory, and the keys never leave the TPM. Trusted platform modules can also play a role in secure boot as a special sequence initialized only by the correct software, in the correct order, to “unlock” the TPM.

What level of hardware security is appropriate for your application will vary, based on your deployment’s risk profile, the capabilities of your device, and the technologies supported by your server-side infrastructure. What is important is that some consideration is made for securing your device at the hardware level, and that you and your device manufacturing partner are united in your approach to telematic hardware security.

Software Security Onboard a Device

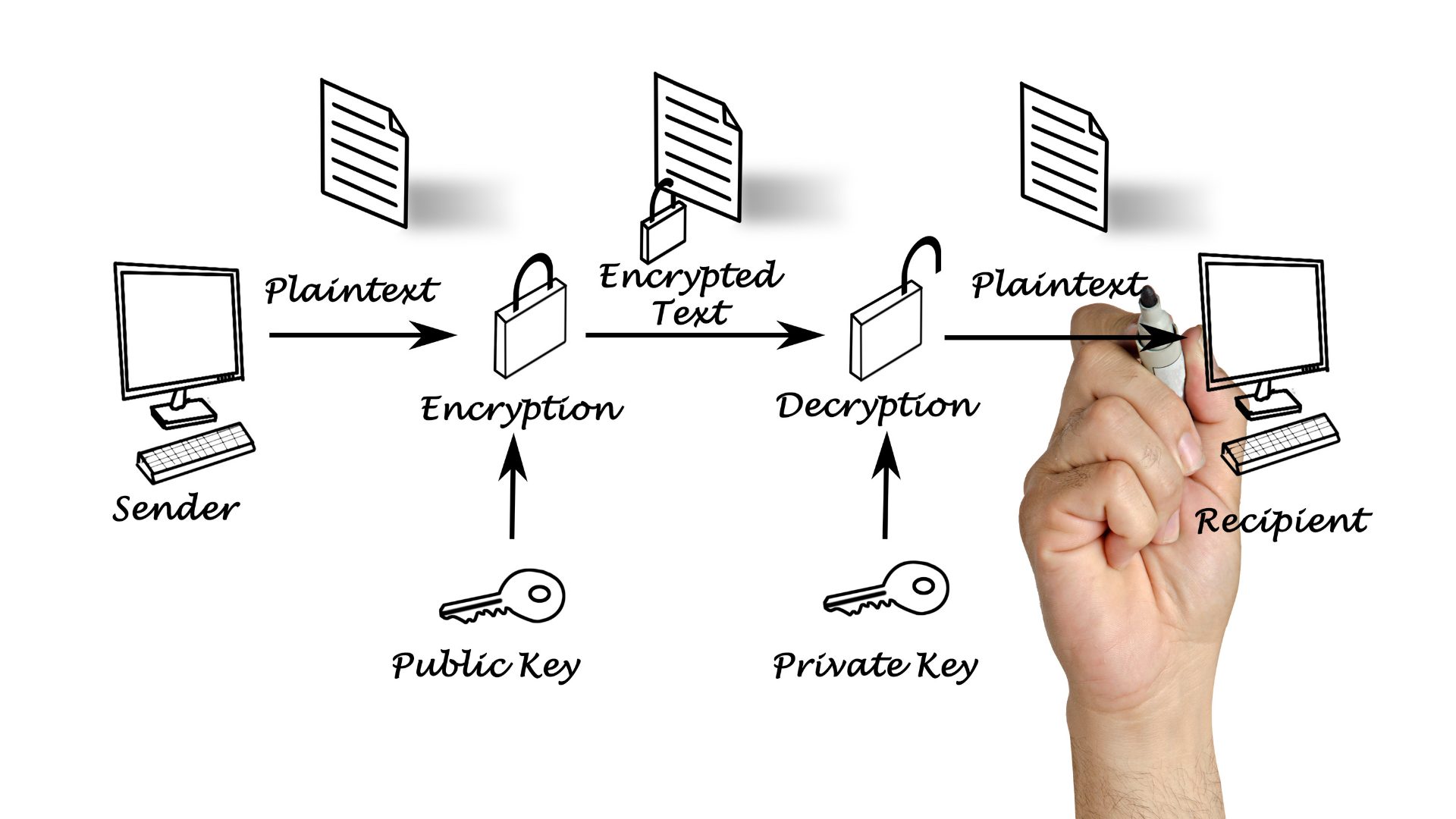

With good hardware security and key storage in place, the updating of the application onboard the device itself can be secured, regardless of whether that update is through firmware updated over the air, or by connecting physically to a device. This security ensures that no bad actor can replace or modify the software onboard your device. This security is achieved by having the application signed with a secret/private key. The signing of this application ensures that the device can verify that the software is genuine, or trusted, before allowing the software to be run on the device.

When transmitting data, there is the protocol being used to transmit data and the method of security that is applied to that protocol. Typically the security and protocol are separate considerations. So whether you are using a popular telematic protocol like MQTT or a UDP IP based protocol like CoAP, there are methods by which that data can be encrypted in its transfer from the device to the Internet, where it then transits to the server. In this sense, most typical security concerns are focused on the data’s pathway through the Internet on its way to its server location more so than the radiation of the data in free space from the device’s antenna.

In the world of data encryption there are two high-level concepts that are important to understand: symmetric encryption and asymmetric communication of data.

Symmetric Encryption

Symmetric encryption is when you open a “secure channel.” If you think about the President of the United States and the red phone for secure calls, that is a very good analogy for symmetric encryption. This is a secure two-way channel for communication. For applications where the receiver and sender are in the same organization, or the device and end-point receiving the data are designed by the same company, this system is commonly and effectively employed. This technology is commonly used in applications like banking transactions and data at rest (not in transit from one server to another).

Symmetric encryption is when you open a “secure channel.” If you think about the President of the United States and the red phone for secure calls, that is a very good analogy for symmetric encryption. This is a secure two-way channel for communication. For applications where the receiver and sender are in the same organization, or the device and end-point receiving the data are designed by the same company, this system is commonly and effectively employed. This technology is commonly used in applications like banking transactions and data at rest (not in transit from one server to another).

Asymmetric Encryption

In this method of security, there is a public key that can be used to encrypt data to be sent to a receiver, but a secret key that is possessed by the receiver is the only way to decrypt the data. Where different organizations are communicating with one another, or when several organizations might be contributing data to a common dataset, such a security methodology is very effectively used. Asymmetric encryption is commonly used in applications like digital signatures and is a feature of transport layer security (TLS) or secure socket layer (SSL) communications.

One of the shortcomings of asymmetric encryption is that it is much slower to implement and use on devices because the encryption algorithms are complex and require more computational power to run. This is unfortunate for embedded devices where processing capabilities are often a significant limitation. Although symmetric encryption doesn’t require as much computational power, it requires that secret keys be effectively distributed and maintained, which is a separate challenge.

Hybrid Approach

With consideration for the challenges above, it is common in messaging and telematic applications to employ a hybrid model. With this model, an asymmetric message is used to open a secure channel and exchange keys to begin the session between the client and the host, so that session can subsequently be done with safe, secure, lower-overhead symmetric encryption. For example, the client can use a public key to send a message to a host describing all of the information the host needs to connect back to the client using symmetric encryption (a shared secret key).

No One-Size-Fits-All Approach

A good security strategy is a collaborative effort between the device manufacturer and the OEM. For example, in a simple asset tracking use case with a battery powered asset tracker that needs to optimize battery life for a longer duration, the asymmetric public key transfer could use 6k of data in the process of sending a one-time 500-byte message. That means that throughout the life of the device, more than 90% of the precious battery life the device is trying to optimize for would be consumed securing the device’s messages. In such cases, like inexpensive IoT sensors feeding asset tracking or environmental intelligence to machinery management systems, the costs in battery life and data transmission may necessitate other approaches to message security.

In a future blog article we’ll cover how a device manufacturer, in collaboration with the cellular or satellite carrier, can be creative in the manner that data is received off the device at the network infrastructure to keep that data off the internet and further contribute to a security solution. Approaches like this can be of considerable assistance when combatting power/data budgets for use cases like the above IoT sensor.

Summary

When considering your connected vehicle deployment, ensure you and your device manufacturer have hardware level key security, signed certificates for software deployment, and a right-sized strategy for encryption of communication to/from the device.

David Batcheller – President & CBO

David Batcheller – President & CBO

https://www.appareo.com/2020/12/07/top-two-security-issues-for-connected-machines/

Guest Blog: A Bench Tech’s Thoughts on USB Device Interference in Aircraft

A Few Thoughts on USB Device Interference in Aircraft

Jim Karpowitz, Avionics Technician

A few years back I attended an evening concert by a wonderful artist whose music I very much enjoy. That particular night, however, the person sitting next to me insisted on singing along with every song. This individual was enthusiastic but was also tone deaf and monotonic. The skill of the artist was no match for the caterwauling coming from the seat next to me. As a musician myself, the dissonance was at the threshold of pain and the only way I could enjoy the concert was to move to another seat. In other words, I had to get clear of the noise source to receive the desired signal.

This is how your avionics feel in the presence of consumer grade portable devices and power supplies that have a tendency to radiate electromagnetic interference, or EMI. EMI has become a serious concern in a number of industries because of radiated interference from power supplies, lighting systems, computer systems and peripherals and other noise sources creating interference to everything from television and radio broadcast to wireless microphone systems to amateur and commercial communications.

Avionics are not immune to interference either. In the aircraft environment, the use of portable digital devices has increased greatly over the last few years and these devices can and do generate substantial amounts of interference. I have diagnosed numerous cases of interference and have found that cigarette lighter USB power supplies are some of the greatest offenders, often dropping incredible amounts of interference within the nav and com bands. The result can be anything from intermittent squelch break to serious interference with desired signal reception.

Avionics are not immune to interference either. In the aircraft environment, the use of portable digital devices has increased greatly over the last few years and these devices can and do generate substantial amounts of interference. I have diagnosed numerous cases of interference and have found that cigarette lighter USB power supplies are some of the greatest offenders, often dropping incredible amounts of interference within the nav and com bands. The result can be anything from intermittent squelch break to serious interference with desired signal reception.

Often people will try to address the intermittent squelch break issue by turning up the squelch threshold. It’s the wrong approach, rather like hanging a candle in an outhouse. The first rule of noise mitigation is to deal with the interference at the source. I cannot overstress the importance of addressing the interference itself rather than masking it in the receiver. Often this means investing in devices (USB supplies, for example) that have gone through the process of testing and approval for aircraft use, giving the user some assurance that a) it does not interfere with on-board systems and b) on-board systems won’t interfere with it, to say nothing of testing for safety issues such as overload and fire protection.

We all want to save our dollars where possible, but trying to save money by using untested/unknown devices is penny wise and dollar foolish. Some consumer grade devices may interfere, some don’t. The point is, without some level of testing and certification, it’s a complete crap shoot, and aviation is no place to be rolling the dice.

Jim Karpowitz is an avionics technician in Wisconsin.

https://www.appareo.com/2020/12/02/guest-blog-a-bench-techs-thoughts-on-usb-device-interference-in-aircraft/

G1000 NXi Adds Integration With Blackhawk Engine+ Upgrade for King Air 300 and King Air 350

Our G1000® NXi flight deck is now available for integration with the Blackhawk Aerospace XP67A Engine+ Upgrade for the King Air 300 and King Air 350, adding a significant benefit to those looking to maximize these aircraft. Additionally, we have expanded its Supplemental Type Certificate (STC) approval to now include King Air 350 aircraft with a max gross weight of 16,500 lbs.1, bringing enhanced capability to operators looking to maximize payload and efficiency.

“We are pleased to offer this new Blackhawk engine interface with the G1000 NXi flight deck for the King Air 300 and 350 models,” said Carl Wolf, Garmin vice president of aviation sales and marketing. “In doing so, we’ve answered our customers’ requests to include this engine upgrade interface to our system, which will even further improve performance for the King Air 300 and 350 models. Additionally, we have now certified the G1000 NXi flight deck in the high gross weight configuration for the King Air 350, which will significantly benefit special missions operators, or any other operator who has been seeking this higher gross weight capability, along with G1000 NXi in the cockpit.”

Blackhawk Aerospace Engine Support

The Blackhawk Aerospace XP67A Engine+ Upgrade for the King Air 300 includes two factory-new Pratt & Whitney PT6A-67A engines and Hartzell 5-bladed composite propellers, combined to deliver maximum cruise speeds as high as 343 knots true air speed (KTAS) with an initial rate of climb up to 4,000 feet per minute (FPM). This performance increase results in only 19 minutes to climb from sea- level to flight-level 350 – half the time compared to a King Air 300 without this upgrade. Blackhawk Aerospace is a popular provider of King Air upgrades, already offering an engine upgrade for the King Air 350 that integrates with the G1000 NXi.

“There are so many advantages in upgrading legacy King Air’s with modern engineering marvels from Garmin and Blackhawk,” said Edwin Black, Blackhawk senior vice president of sales and marketing. “The Garmin G1000 NXi is arguably the most sophisticated, user-friendly, and light-weight avionics masterpiece ever certified for the King Air market. It is rewarding to work closely with the Garmin team to empower our mutual customers with the most compelling investments an operator can make to maximize performance and safety.”

Increased gross weight STC

With the latest G1000 NXi approval, King Air 350 owners and operators can now take advantage of an increased payload, providing significant performance enhancements that can prove to be particularly beneficial to special missions operators. Along with the separate STC modifications, support for G1000 NXi equipped King Air aircraft is now available via an enablement.

The G1000 NXi integrated flight deck upgrade for existing G1000-equipped King Air 300 and King Air 350 is available immediately through select Garmin dealers. King Air 300 and 350 owners and operators can easily upgrade to the G1000 NXi with minimal aircraft down time and panel disruption as the displays preserve the same footprint and connectors, so panel modifications are not required. The upgraded components of the G1000 NXi also come with a two-year warranty, which is supported by our award-winning avionics product support team. For additional information regarding the G1000 NXi upgrade for the King Air 300 and King Air 350, contact Scott Frye at scott.frye@garmin.com, or visit www.garmin.com/KingAir. The Blackhawk Aerospace XP67A Engine+ Upgrade for the King Air 300 and King Air 350 is available immediately through Blackhawk Aerospace, and the increased gross weight STC for the King Air 350 is available from Textron Aviation.

- This STC has been shown to be compatible with Textron Heavyweight Kit Installation, part number 130-4030-0001, 130-4030-0003 or 130-4030-0005 (as applicable by aircraft serial number), for B300 serial number FL-584 through FL-1030 (excluding FL-954 and FL-1010) and B300C serial number FM-25 through FM-65 or with production Textron B300 and B300C Heavyweight aircraft.

The post G1000 NXi Adds Integration With Blackhawk Engine+ Upgrade for King Air 300 and King Air 350 appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/g1000-nxi-adds-integration-with-blackhawk-engine-upgrade-for-king-air-300-and-king-air-350/

Easy, Convenient Flight Logging with Garmin Products and flyGarmin.com

Flight logging hasn’t really changed over the years. The manual tradition of putting pen to paper, adding flight details, noting endorsements and maintaining flight times as best as possible in a logbook is as relevant today as it’s ever been. And while this customary process is still widely employed, it can sometimes feel antiquated, time-consuming and cumbersome. Now, with select Garmin avionics, the Garmin Pilot app and D2

app and D2 series aviation watches, we’ve modernized this process by adding automation and digitalization. With these tools, pilots and aircraft owners can simplify the age-old flight logging process while gaining powerful insights on every flight.

series aviation watches, we’ve modernized this process by adding automation and digitalization. With these tools, pilots and aircraft owners can simplify the age-old flight logging process while gaining powerful insights on every flight.

Logging flights with Garmin aviation smartwatches

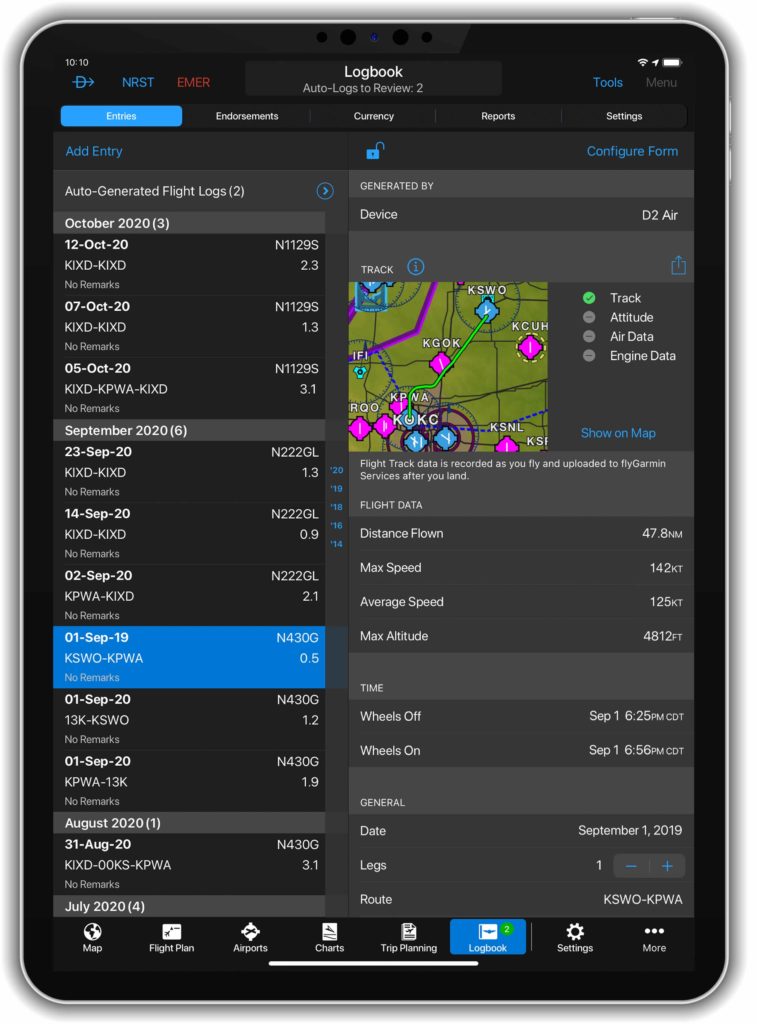

Our latest D2 series aviation watches – the D2 Air and D2

Air and D2 Delta series – can automatically detect the change in altitude during takeoff, initiating a flight recording logbook function. Once activated, it records the date, duration, total flight time and route. Upon landing, the information is automatically synced to a digital logbook on Garmin Pilot and flyGarmin.com – our safe and secure web-based cloud service – via a compatible smartphone.

Delta series – can automatically detect the change in altitude during takeoff, initiating a flight recording logbook function. Once activated, it records the date, duration, total flight time and route. Upon landing, the information is automatically synced to a digital logbook on Garmin Pilot and flyGarmin.com – our safe and secure web-based cloud service – via a compatible smartphone.

Air featuring flight logging capabilities.

Air featuring flight logging capabilities.Log flights, endorsements, track currency and more with Garmin Pilot

Our Garmin Pilot app can take flight logging a step further. In addition to automatically logging flights from takeoff to landing like the D2 Air and D2 Delta series, Garmin Pilot can record remarks, endorsements and help keep track of currency based on the number of takeoffs and landings in either day or night conditions.

Additionally, when operating Garmin Pilot from a GPS-equipped mobile device, or when it’s connected to a compatible external GPS device, it can automatically record flight track data during flights. With this feature enabled, flight data is recorded in-flight, then attached to the logbook entry upon landing. Recorded flight tracks can then be reviewed on the Garmin Pilot map page or flyGarmin.com.

Wirelessly transfer engine performance data with Garmin avionics

Our flight logging feature set doesn’t just apply to the pilot’s flight time – we’ve created tools to help aircraft owners and operators gain valuable insights into their aircraft too. For aircraft equipped with a Garmin GI 275 EIS, an EIS-capable TXi flight display, G1000® NXi, G3000®1 or G5000®1 integrated flight deck, engine data can be wirelessly transmitted to Garmin Pilot on Apple® devices via our Flight Stream 510 wireless gateway2. For example, during a flight, crewmembers can transmit engine data to Garmin Pilot for real-time performance review. Upon landing, aircraft service technicians can review the flight data to help identify performance issues or maintenance needs. Saved performance data is automatically uploaded to flyGarmin.com and viewable on the logbook page.

Review flight and engine data online at flyGarmin.com

Once flights are logged on select Garmin avionics3, D2 Air, D2 Delta series watches and Garmin Pilot, they are safely and securely stored on flyGarmin.com. From a desktop computer, tablet or mobile device, aircraft operators can review flight entries, flight tracks, engine performance data, currency reports and more. When it’s time to report hours and endorsements to employers or insurance, daily, monthly or yearly lookback reports can be generated on flyGarmin.com.

Exceedance alerts can be also be created on flyGarmin.com. This customizable tool can help operators monitor the health of their airframe and engine. A user-configured system limit is set at flyGarmin.com, then an email notification is sent to the operator upon landing if a limit was exceeded. Exceedance alerts can be generated for cylinder head temperature, oil temperature, aircraft pitch and more.

For more information about our flight logging solutions, engine information systems and avionics, visit Garmin.com/aviation.

1Compatibility varies by aircraft and system software level; see aircraft manufacturer for details

2Not required for GI 275 EIS

3Select Garmin avionics require a Flight Stream 510 (sold separately) and Garmin Pilot to do the automated transfer to flyGarmin.com — this transfer can also be done manually with SD card uploads

iPad, iPhone and Apple are trademarks of Apple Inc., registered in the U.S. and other countries.

The post Easy, Convenient Flight Logging with Garmin Products and flyGarmin.com appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/easy-convenient-flight-logging-with-garmin-products-and-flygarmin-com/

New G1000 NXi and G1000H NXi eLearning Courses Available

Pilots who fly behind our G1000® NXi and G1000H NXi for helicopters now have additional opportunities to refine their avionics skills. Our aviation training team introduced two new eLearning training courses for the G1000 NXi, as well as two separate eLearning courses for the G1000H NXi for helicopters. These courses are available in a virtual format allowing pilots to learn at their own pace. The G1000 NXi Fundamentals eLearning Course provides a foundational understanding of the system, while the G1000 NXi Essentials eLearning Course is focused on systems installed in high-performance piston and turbine engine aircraft. The two comprehensive eLearning courses for the G1000H NXi integrated flight deck titled G1000H NXi Fundamentals, and G1000H NXi Advanced-IFR, use scenario-based training to highlight helicopter-specific operations and are tailored for pilots new to the G1000H NXi system, in addition to those with experience wanting a deeper understanding of the system.

Core training topics

All four training courses build on a common core of training topics. These topics are common to all G1000 NXi and G1000H NXi systems but are tailored to the audience for each course. The topics include:

- Primary Flight Display (PFD) and Multifunction Display (MFD) function

- Audio Panel Features

- Automatic Flight Control System

- Hazard Avoidance Features

- Safety Features

- Abnormal Operations

- Managing Databases

- Operational Flight Scenario

Learn best-practices for G1000 NXi operational use

For those that are new to Garmin avionics, transitioning to advanced avionics, or perhaps want to refresh their understanding of the system, the G1000 NXi Fundamentals eLearning Course provides comprehensive training on the system designed for piston engine equipped aircraft. This course describes features of the system in detail and use a scenario to demonstrate how particular features function in different phases of flight in order to see this advanced system in action. In order to practice what you learned during this course, the Garmin G1000 NXi PC Trainer software is available for purchase online.

G1000 NXi for high-performance piston and turbine aircraft

For those operating high-performance piston or turbine-engine equipped aircraft, the G1000 NXi Essentials course presents best-practices for the G1000 NXi integrated flight deck by providing detailed training for pilots wanting to get the most out of the system. In addition to describing features in detail and showing how they can be used effectively in flight, scenario-based training demonstrates typical high-performance piston and turbine-engine aircraft operations, providing an opportunity to see the G1000 NXi system in full effect. For your specific or similar aircraft, the Garmin G1000 NXi PC Trainer software is available for purchase online, and provides the opportunity to take what you learned throughout the course and apply it. In addition to the core training topics, the G1000 NXi Essentials eLearning Course includes additional instruction on:

- Vertical Navigation

- Automatic Flight Control System

- Advanced Features

- User Waypoints

- Managing Databases

- Multiple Operational Flight Scenarios with different performance profiles

Build helicopter-specific system knowledge

The G1000H NXi Fundamentals course is designed for VFR helicopter pilots who are new to Garmin avionics, transitioning to advanced avionics, or perhaps want a refresher on the G1000H NXi. This allows the pilot to be comfortable with the avionics and maximize learning during valuable flight time. Learn how to take full advantage of the capabilities of the G1000H NXi system while gaining experience with operational use best practices. This virtual course allows pilots to learn at their own pace, details system features and provides a VFR flight scenario to show how these features are used in various phases of flight. Those that sign up for this course receive an additional scripted scenario for more practice through the Bell 407GXi G1000H NXi PC Trainer software, available for purchase online. The core training topics in the G1000H NXi Fundamentals eLearning Course have been tailored to helicopter-specific features and functionality, including differences for:

- PFD and MFD function

- Audio Panel Features

- Hazard Avoidance Features

- Operational Flight Scenario

- Scenario-Based Exercise

Enhance IFR helicopter skills with G1000H NXi

The G1000H Advanced-IFR course provides a detailed look at the G1000H NXi system and illustrates best practices for operational use of the flight deck, with a focus on Instrument Flight Rules (IFR). The course uses phase of flight scenarios to demonstrate typical IFR helicopter operation, and depicts common practices to maximize the benefits of system features and capabilities. For helicopter pilots who fly search-and-rescue missions, emphasis on user waypoints are included in the course scenarios. Pilots can further practice what they learned throughout the course with one of the additional scripted scenarios provided for use with the purchase of the Bell 407GXi G1000H NXi PC Trainer software. Some helicopter-tailored training topics covered in the Advanced IFR eLearning Course include:

- PFD and MFD function

- Automatic Flight Control System

- Hazard Avoidance Features

- Advanced Features

- User waypoints

- Operational Flight Scenarios

Proceed through the course at a pace that works best

Available immediately after purchase using a computer or tablet device with internet access, pilots can navigate through the virtual course at their own pace. Assessments throughout the course validate knowledge obtained of critical items while documenting the learning process. With the ability to pause lessons as needed to return to the lesson later, this is a convenient option for any pilot. Also, pilots can retake specific lessons or even the entire course during the subscription period.

The G1000 NXi Fundamentals eLearning course is available now for $94.95 USD, and the G1000 NXi Essentials eLearning Course is now available for $145.95 USD. Also available is the G1000H NXi Fundamentals eLearning Course for $74.95 USD, as well as the G1000H NXi Advanced IFR eLearning Course is available for $94.95 USD. For aviation training needs, including purchasing one of these eLearning courses, please visit www.fly.garmin.com/training.

For additional information, please contact aviation.training@garmin.com.

The post New G1000 NXi and G1000H NXi eLearning Courses Available appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/new-g1000-nxi-and-g1000h-nxi-elearning-courses-available/

Garmin Pilot Adds Graphical Airspace and Obstacle NOTAMs, Updated Flight Profile View

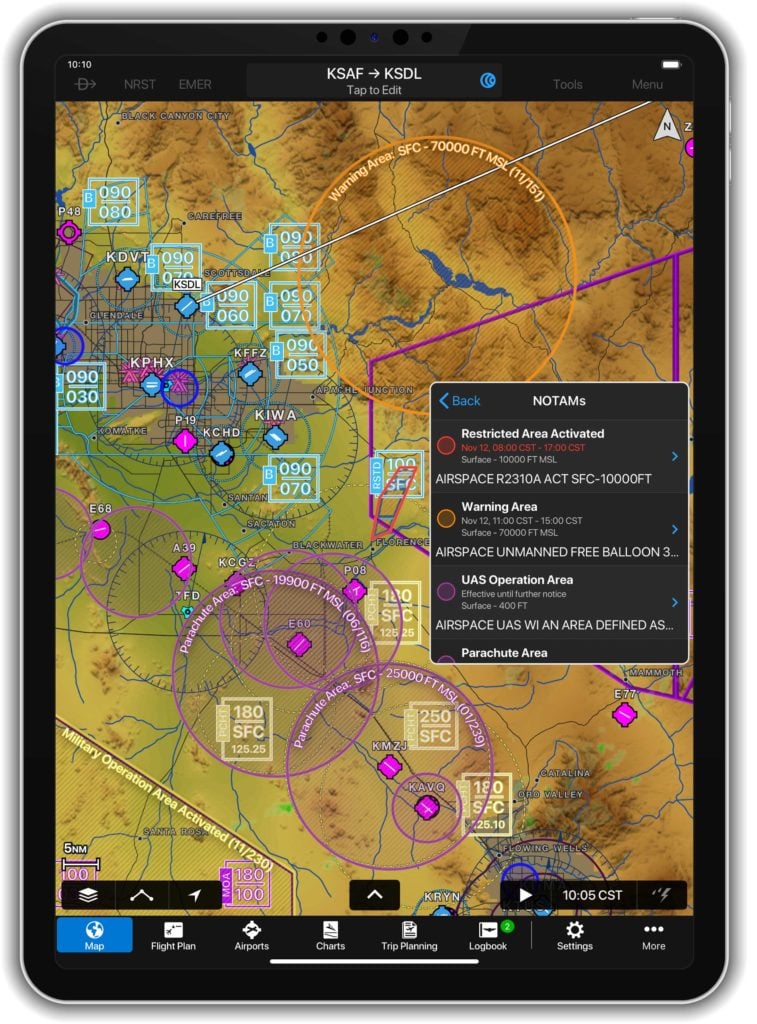

Our Garmin Pilot app for Apple mobile devices now offers pilots the ability to reference graphical airspace and obstacle NOTAMs during pre-flight planning, and inflight for increased situational awareness. An enhanced user interface for Profile View also provides pilots the ability to access important information such as weather, PIREPs, and more, faster than ever before.

Graphical Airspace NOTAMS

Airspace NOTAMS are now available as a graphical overlay on the map. They can be depicted as a circle or other shape with the type and associated altitude of the NOTAM labeled for even more clarity depending on the selected zoom level. NOTAMs that are scheduled to become active in the next 24 hours are displayed in yellow to help alert pilots in advance and aid with flight planning, with a brighter contrast for areas showing upcoming restricted airspace. Active airspace NOTAMs are color-coded depending on the following classifications:

- Red: Restricted and Danger NOTAMs, such as Prohibited Areas

- Orange: Alert and Warning NOTAMs, including Military Operation Areas (MOA)

- Gray: Flight Data Center (FDC) NOTAMS such as Instrument Approach Procedure changes

- Purple: Other NOTAMs such as Parachute Jumping areas

For convenience, airspace NOTAMs can be viewed from either the map or flight plan page by selecting the NOTAMs layer from the map overlays menu. Pilots can view NOTAMs in both decoded and raw text by selecting the NOTAM segment in the radial menu. Further, NOTAMs may also be viewed by selecting the NOTAMs widget in spilt-screen mode.

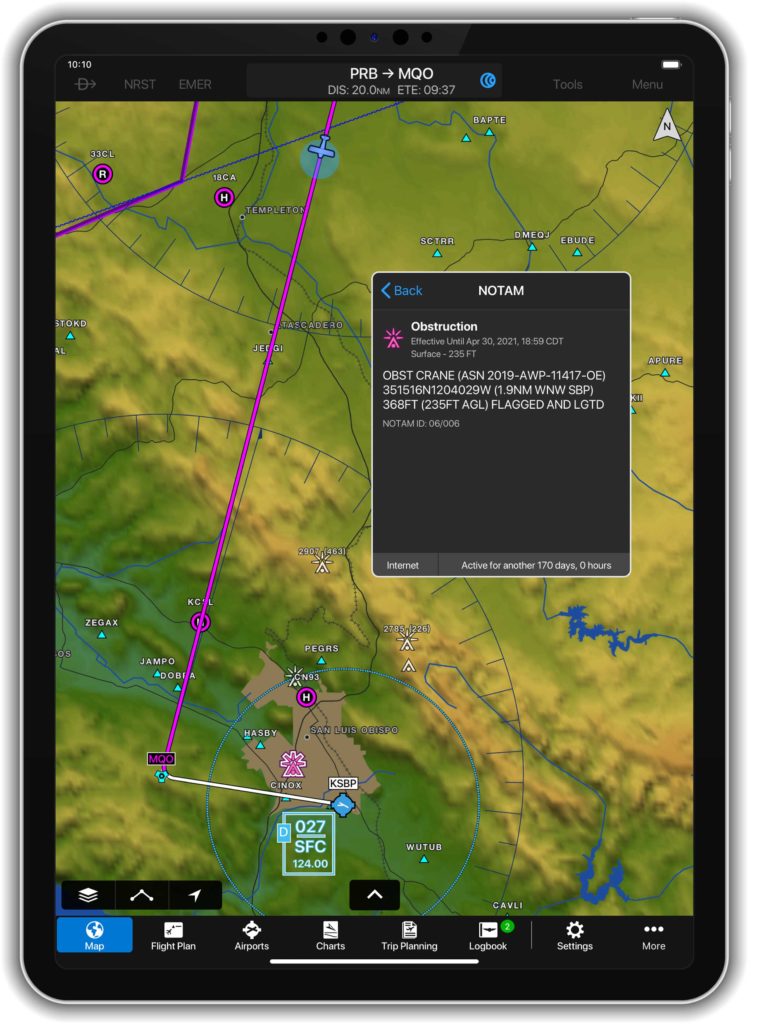

Graphical Obstacle NOTAMs

Obstacle NOTAMs use pink obstacle figures on the map in order to differentiate obstacle NOTAMs from permanent obstacles and are displayed anytime the NOTAM or obstacle layer is enabled. Those obstacles that have since been removed are displayed for reference as a pink “X.” Obstacle NOTAMs are available from the map or flight plan page by selecting overlays from the map layer icon with the ability to be viewed in both decoded and raw text by selecting the obstacle segment in the radial menu. Also, for convenience pilots have the ability to view an Obstacle NOTAM list from the airport page and by tapping the map icon for a selected NOTAM, jump to that NOTAM right on the map.

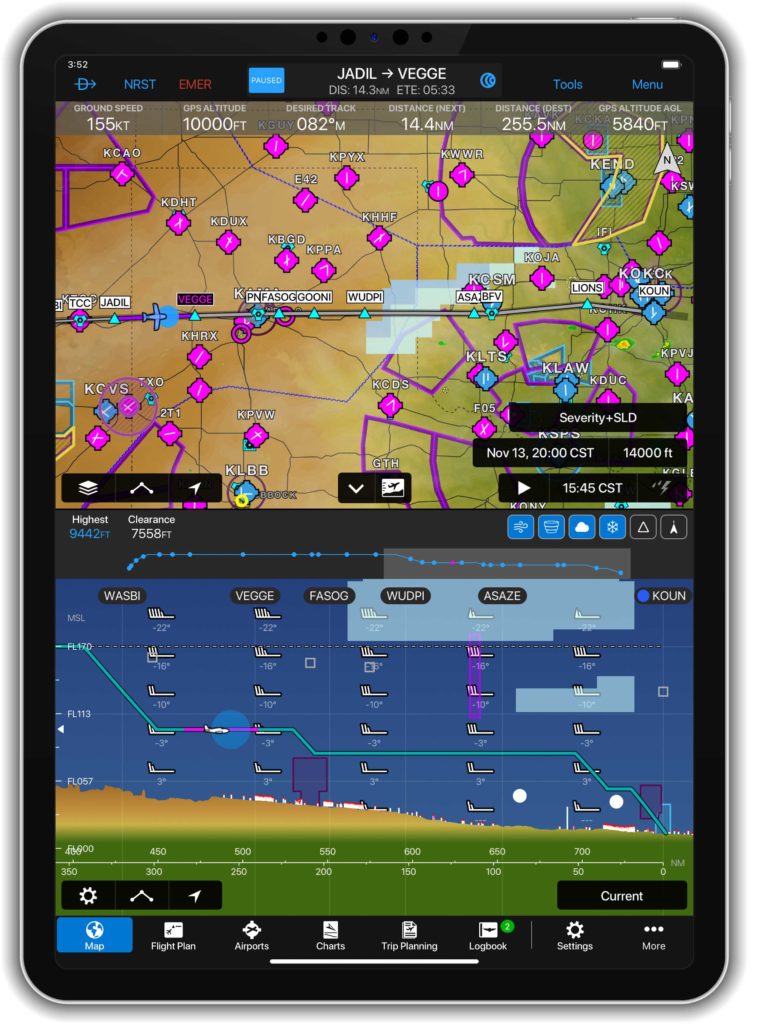

Enhancements to the Flight Profile View

The new quick access bar in the Flight Profile View allows pilots to display critical flight information such as weather, PIREPs, and traffic from compatible Garmin ADS-B traffic sources with just a single touch. Using the new and simple Pinch-to-Zoom capability, pilots now have the ability to more seamlessly review parts of the flight by focusing on a particular segment in the Profile View while still being able to reference the basic flight profile above.

The newest release of Garmin Pilot, version 10.3 for Apple mobile devices is available immediately. For new customers, Garmin Pilot is available in the Apple App Store as a free download for the first 30 days. After the 30-day trial period, customers may purchase an annual subscription of Garmin Pilot starting at $79.99. Garmin Pilot is supported by our award-winning aviation support team, which provides 24/7 worldwide technical and warranty support. Please visit www.garmin.com/aviation for additional information.

The post Garmin Pilot Adds Graphical Airspace and Obstacle NOTAMs, Updated Flight Profile View appeared first on Garmin Blog.

https://www.garmin.com/en-US/blog/aviation/garmin-pilot-adds-graphical-airspace-and-obstacle-notams-updated-flight-profile-view/